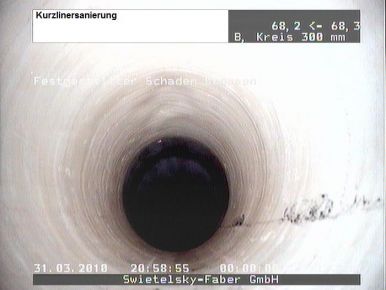

Short liners / Long liners

On the safe side — in every respect

The short liner system we install is based on ECR glass laminate, which can also be built up layer for layer, depending on the structural demands in individual cases, and impregnated with a silicate resin system. Installation is realised following thorough prior cleaning of the damaged area with the aid of a pneumatic packer system and generally takes no longer than three hours, including the time required for cold curing. As through-flow packers are used, the dry weather drain can be maintained in most cases during rehabilitation. The system installed by us is environmentally compatible in every respect and has building inspection authorisation issued by the German Institute for Structural Engineering (DIBT). You are therefore on the safe side in every respect with our short and DIN liners.

Versatile use and flexible application: short liners

The short liner system is used for the rehabilitation of:

- leaking pipe connections

- all-round cracks

- shards and surface defects

- individual corrosion areas

- intruding root formations

- infiltration and exfiltration

Short liner technology is designed to rehabilitate damaged areas from 50 centimetres to 4 metres in length. Our short liners can be used as effectively in circular profile short liners from DN 100 to DN 800 and oval profiles up to 500/750 and employed in pipes made of any material except PE-HD. The highly flexible glass fibre laminate enables installation in pipe bends up to 90°.

Fits, sits and supports: the outcome of rehabilitation

The cured short liner has a wall thickness of three to five millimetres, depending on the structure involved. By discharging excess resin onto the surface of the old pipe, the short liner ensures not only a friction bond, but also a non-friction bond where the damaged area is cleaned thoroughly in advance. The high static parameters of corrosion and abrasion-resistant materials ensure that the short liner restores stability in the defective area without impairing the flow rate in a noticeable manner. The result achieved with the short liner therefore provides a rapid and environmentally compatible, cost-effective and sustainably effective rehabilitation solution for practically every defective area.

Swietelsky-Faber GmbH Kanalsanierung

Hauptstraße 2

D-55483 Schlierschied

Tel.: +49 (0) 67 65 94 93 79 0

Fax: +49 (0) 67 65 94 93 79 90